The Challenge A large racking manufacturer required a current state production roadmap and longer-term facility strategy to meet a significant growth opportunity. The company had multiple facilities spread across a medium sized market creating significant transportation and labors costs while creating production bottlenecks. The leadership team needed a thought partner to assist in understanding the… Read More

The Challenge Over a 3-year span our client expanded their operating footprint with the acquisition of 5 business with little integration. The rapid growth caused conflicting messaging across the enterprise and a siloed approach to core business functions including Sales, Product Development, Pricing, Engineering, Supply Chain, Scheduling and Manufacturing. The lack of synergy and adoption… Read More

The Challenge A Fortune 1000 life sciences company engaged TriVista to support the carve out and sale of a >$1B division. After completing the transaction, the seller needed to execute pre-sale post-close plans to fulfill their obligations to the buyer. This included achieving 1-Day, 30-Day, and 90-Day transition milestones, maintaining stable operations under the Transitional… Read More

The Challenge A leading designer and manufacturer of medical equipment recently acquired a competitor and wanted to consolidate the manufacturing sites. They chose the acquired company’s site as the final location. The company needed help to move its existing production facility. The company brought TriVista on to help consolidate the manufacturing sites. Our Approach Analyzed… Read More

The Challenge A leading designer and manufacturer of medical equipment recently acquired a competitor and wanted to consolidate the manufacturing sites. They chose the acquired company’s site as the final location. The company needed help to move its existing production facility. The company brought TriVista on to help consolidate the manufacturing sites. Our Approach TriVista… Read More

The Challenge A client engaged TriVista to provide acquisition integration support relating to the integration of two leading medical device manufacturers. The scope of the integration included all SG&A, Operations, and IT including ERP harmonization. Our Approach Our team of experts broke down the engagement with the following approach: Conducted multiple site visits with key… Read More

The Challenge Several clients across the automotive, lumber, and plastics industries were facing rising input costs without a clear understanding of cost drivers. Poor visibility into the cost structures of commodities, goods, and services contributed to their margin compression. These businesses sought an expert partner to uncover hidden cost-saving opportunities through an accurate benchmarking process…. Read More

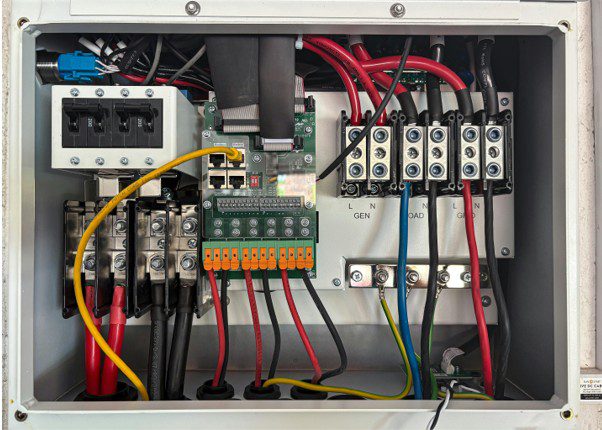

Leading manufacturer of intelligent metering systems The Challenge A leading manufacturer of intelligent metering systems was looking to mitigate geopolitical and single-source risks in their supply chain. With 50% of components sourced from China and PCBAs*, metal parts, and batteries reliant on single sources, TriVista was tasked with identifying alternative suppliers to ensure high-quality continuity… Read More

Manufacturer of liquid fill products serving global brands and retailers The Challenge A leading wet wipes manufacturer sourced most of its supply chain in the US but recent acquisitions increased sourcing from India and China. The client enlisted TriVista’s support to cut overall material costs by potentially shifting additional categories to low-cost countries (LCC). Our… Read More

A furniture manufacturer. The Challenge A furniture manufacturer hit maximum production capacity in their existing facility. With an estimated 70% increase in year-over-year revenue, the company recognized the need to expand its footprint to accommodate growth. Considering the possibility of opening a second facility, they sought TriVista’s expertise to explore options for increasing production output… Read More

A fast-growing producer and distributor of ethnic food. The Challenge TriVista was hired to conduct a Quality of Operations™, Food Safety, and IT Due Diligence assessment on a producer and distributor of dry packed food goods. Our Approach TriVista conducted a due diligence assessment of key business value streams and associated IT support systems with… Read More

An aerospace and defense company. The Challenge Our client, an aerospace and defense company, engaged TriVista to review the inventory control and management processes at their manufacturing facility. Inventory accuracy was reported between 10-20% after the previous 2 audits resulting in widespread material shortages. Planning and production teams were impacted daily by inaccurate inventories and… Read More

A packaging component manufacturer. The Challenge TriVista was engaged by a private equity firm to perform a Quality of Operations™ Due Diligence assessment on a packaging component manufacturer that was being considered for acquisition. The scope of the analysis included identifying potential acquisition synergies and developing integration strategies for the target company and the portfolio… Read More

A manufacturer of machinery and equipment. The Challenge A private equity firm was looking to acquire a leading manufacturer and importer of machinery and equipment. They brought in TriVista to conduct both an operations and IT due diligence to help identify operational and IT levers that would continue to expand EBITDA and/or reduce current operational… Read More

A label and packaging printing company. The Challenge TriVista was retained by a private equity firm that invested in a label and packaging business. The business had recently merged with a competitor, and our team was tasked with measuring and improving the Overall Equipment Effectiveness (OEE) of their flexographic printing and rewind departments. Our Approach… Read More

A car care products company. The Challenge A private equity-owned car care products company sought to enhance operational performance by focusing on SKU rationalization and inventory management. Rapid growth, driven by organic demand and expansion into new channels, posed challenges in servicing customer orders and optimizing working capital. TriVista was brought in help the business… Read More

A landscaping company. The Challenge TriVista was retained by private equity investors and the leadership team of a landscaping business to provide Quality of Operations™, Information Technology Due Diligence, and cost synergy analysis relating to the possible add-on acquisition of another landscaping company. Our Approach Through site visits with the target company, interviews with the… Read More

Leading distributor of plumbing products acquired by an appliance repair parts distribution company. The Challenge TriVista was retained to provide acquisition integration support relating to the acquisition of a distributor of plumbing products. Client is a leading distributor of OEM branded residential appliance repair parts. Our Approach We performed functional assessments via site visits, detailed… Read More

A seasonings manufacturer with sites in the U.S. and Mexico. The Challenge A private equity client was considering acquiring a food manufacturer of seasonings that use fresh ingredients. The target operates facilities in the U.S. and Mexico. The facilities have undergone recent changes in management and are experiencing market growth as well as implementing operational… Read More