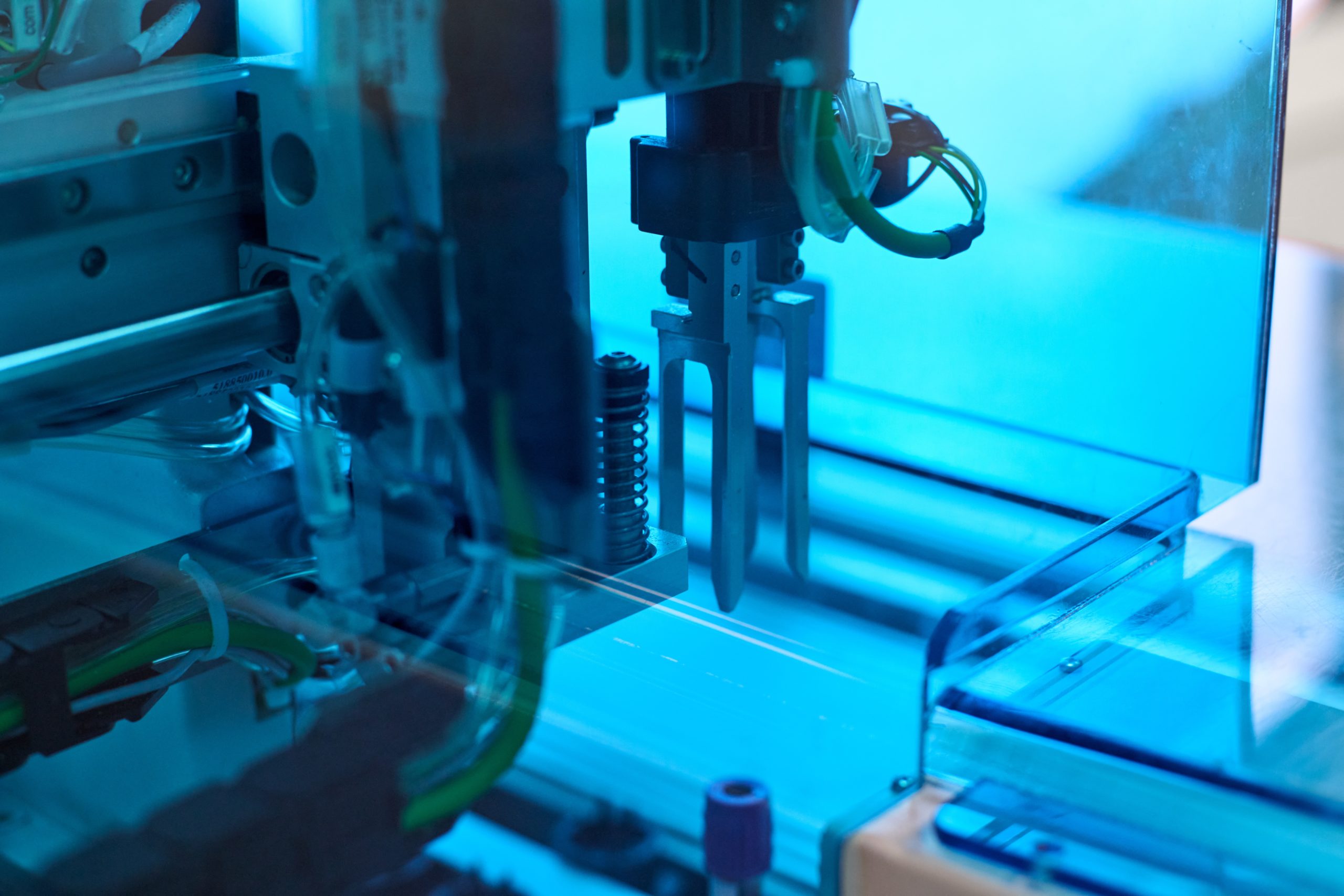

The Challenge A leading designer and manufacturer of medical equipment recently acquired a competitor and wanted to consolidate the manufacturing sites. They chose the acquired company’s site as the final location. The company needed help to move its existing production facility. The company brought TriVista on to help consolidate the manufacturing sites. Our Approach Analyzed… Read More

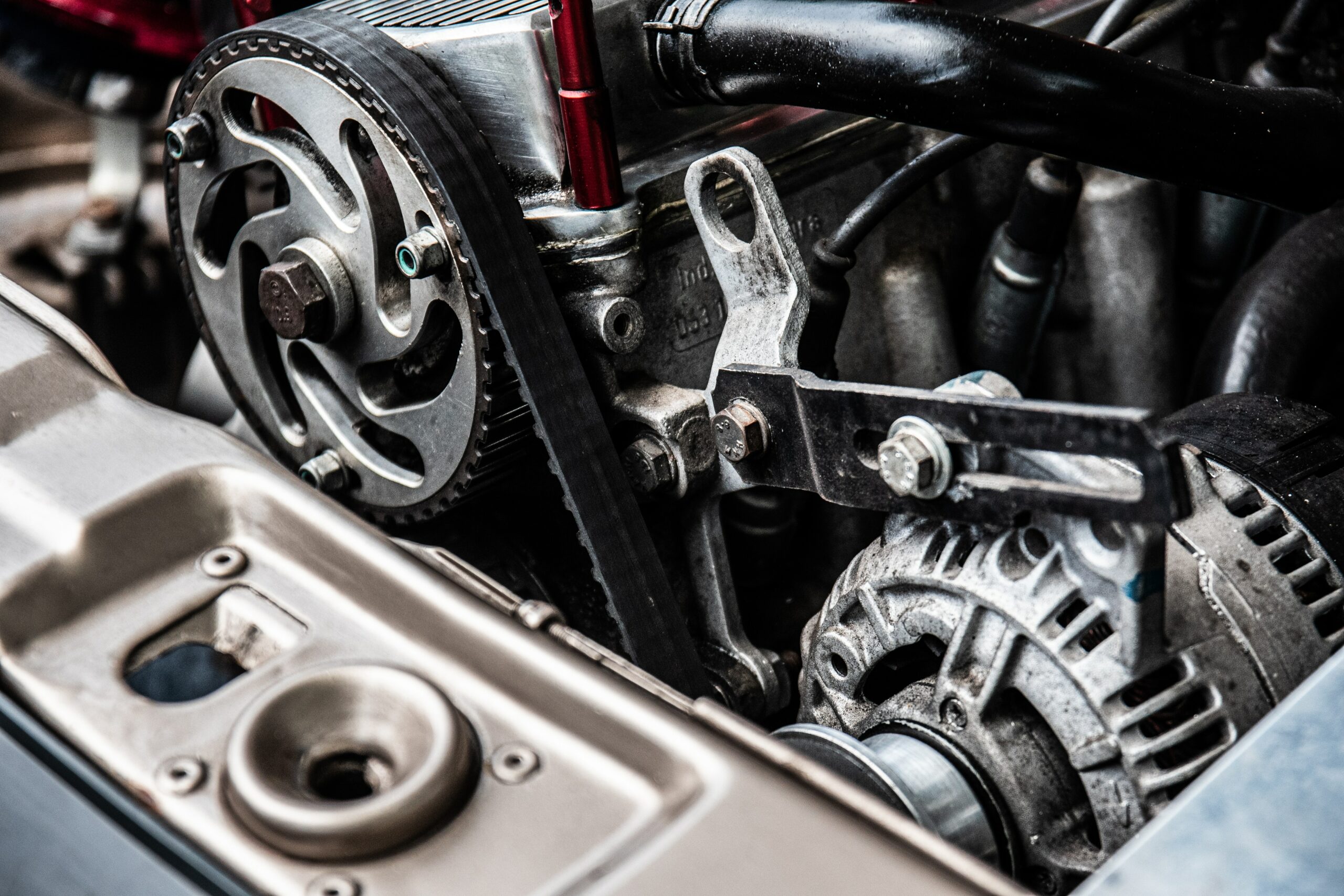

The Challenge Several clients across the automotive, lumber, and plastics industries were facing rising input costs without a clear understanding of cost drivers. Poor visibility into the cost structures of commodities, goods, and services contributed to their margin compression. These businesses sought an expert partner to uncover hidden cost-saving opportunities through an accurate benchmarking process…. Read More

Leading manufacturer of intelligent metering systems The Challenge A leading manufacturer of intelligent metering systems was looking to mitigate geopolitical and single-source risks in their supply chain. With 50% of components sourced from China and PCBAs*, metal parts, and batteries reliant on single sources, TriVista was tasked with identifying alternative suppliers to ensure high-quality continuity… Read More

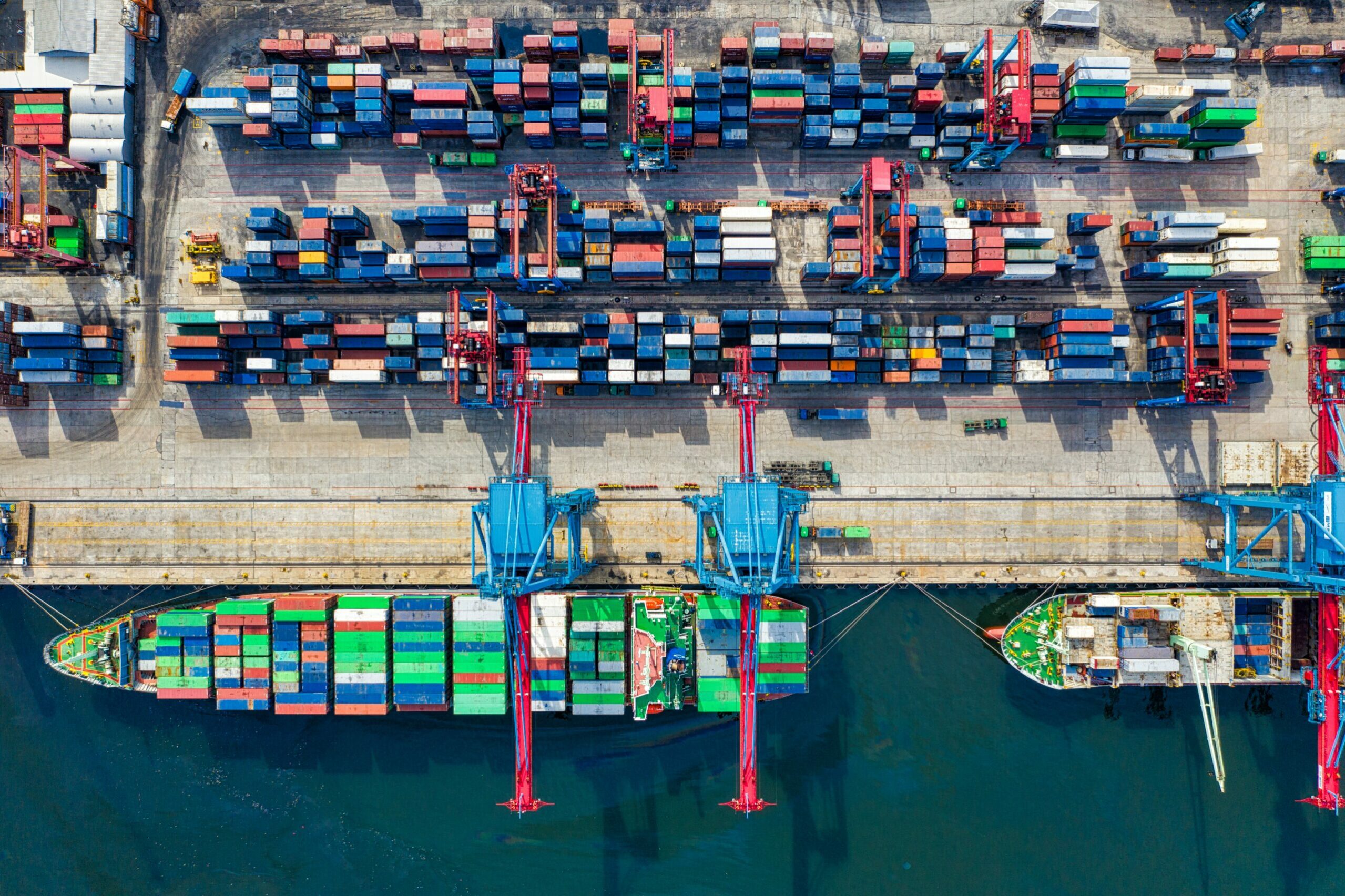

Manufacturer of liquid fill products serving global brands and retailers The Challenge A leading wet wipes manufacturer sourced most of its supply chain in the US but recent acquisitions increased sourcing from India and China. The client enlisted TriVista’s support to cut overall material costs by potentially shifting additional categories to low-cost countries (LCC). Our… Read More

A car care products company. The Challenge A private equity-owned car care products company sought to enhance operational performance by focusing on SKU rationalization and inventory management. Rapid growth, driven by organic demand and expansion into new channels, posed challenges in servicing customer orders and optimizing working capital. TriVista was brought in help the business… Read More

A private-equity backed manufacturer and distributor of industrial electrical components. The Challenge A U.S.-based manufacturer and distributor of electrical components was shipping from 3 warehouses, and all were at or near full capacity. With the company’s aggressive growth plans – both organic and acquisitive – they were looking to better understand their footprint and operations…. Read More

Inventory Analysis Identified $115M of Working Capital Improvement and a $22M Reduction of Inventory

$1B revenue business that manufacturers and supplies replacement parts for the automotive aftermarket. The Challenge A large manufacturer of car parts required significant working capital for acquisition growth and requested support to identify and develop a future inventory model to reduce working capital as well as identify root-cause drivers of current excess inventory. Our Approach… Read More

The Challenge The client – a $4B leading American grocery store operator, with 200+ stores – had a current distribution network consisting of several distribution centers across the region. Due to the relatively condensed network, there were many overlapping shipments and duplications of inventory. The client’s leadership believed there was significant opportunity to optimize both… Read More

The Challenge A private equity backed, global provider of mission critical hardware and plumbing components approached TriVista for assistance in creating a global sourcing strategy to combat recent increases in supply costs of Chinese goods, due largely to imposed tariffs, increased labor expenses, and tighter environmental regulations. The increased costs were passed on to customers… Read More

A rapidly growing $100M+ e-Commerce distributor with a large distribution network across multiple e-commerce platforms ran into capacity constraints due to lack of warehouse space and a large amount of slow-moving inventory, hindering their ability to meet expected growth targets The Challenge With over 7,000 SKUs and plans to bring on an additional 1,500+ SKUs… Read More

TriVista dramatically improved customer service by implementing a robust Sales, Inventory, and Operations Planning (SIOP) Process that decreased stock-outs by 50% without additional inventory. The Challenge TriVista’s client was facing increasing backorders and rapidly declining customer satisfaction. Our team was tasked with developing an improved supplier and inventory management system which would eliminate stock outs… Read More

STRENGTHENING THE SUPPLIER BASE, STREAMLINING LOGISTICS NETWORK, AND EMPOWERING THE LEADERSHIP TEAM The Challenge A $400M in sales revenue, multi-division industrial products manufacturer was experiencing major issues in its Asia and China supply chain. Poor On-Time-Delivery and high logistics costs were forcing the company to absorb substantial price increases, while struggling with poor quality shipments…. Read More

A fashion jewelry leader aligns their supply chain to keep up with rapid sales growth. TriVista’s Diagnostic Process uncovered $10M in EBITDA savings and identified $12M in cash flow improvements. The Challenge A private equity backed retailer of women’s fashion jewelry and accessories was on track to double sales to $1B over the next 3… Read More

The Challenge A Private Equity backed $100M custom printing and packaging company serving the Consumer-Packaged Goods market sought assistance from an operational consulting firm to assess operations and provide actionable plans to improve customer service and expand margins. Our Approach TriVista conducted a 3 week assessment, focused on: Sales & Operations Planning (S&OP) Inventory Management… Read More

The Challenge A $100M company, backed by a middle market private equity firm, focused solely on distributing industrial spare parts from seven warehouses with over 25,000 stock keeping units (SKUs). The company retained TriVista to assist with optimizing their inventory positions across all sites. Our Approach Analyzed current state sales revenue and margin, demand variability,… Read More

The Challenge A $250M fashion jewelry and accessory retailer, backed by a private equity firm, retained TriVista to provide expert supply chain consulting expertise to help them evaluate their current supply chain network. Our Approach DMAIC approach to evaluate existing supply chain and suppliers Benchmarked suppliers to industry standards and identify gaps/weaknesses in current supply… Read More

The Challenge A global, mid-market Private Equity firm seeking to acquire a five-year old start-up consumer products company that specializes in infant and toddler soft goods, retained TriVista to provide Quality of Operations™ Due Diligence with a strong focus on supply chain due diligence. The company was growing exponentially, and was on track to grow… Read More